Zinc and aluminium alloy are two often used and popular materials for chandelier accessories, both with benefits and drawbacks appropriate for various demands and surroundings. Which thus is preferable for chandelier accessories—aluminum alloy or zinc alloy? The features of these two materials will be discussed in this post from several viewpoints so that you might decide with knowledge.

First, one should grasp the fundamental characteristics of aluminium and zinc alloys. Made from zinc, combined with other metal elements, including aluminium, copper, and magnesium, zinc alloy is Widely employed in manufacturing many different industrial items; it has outstanding mechanical qualities and corrosion resistance. Widely utilized in aerospace, automobile manufacture, construction, and home decoration, aluminium alloy—based on aluminium and combined with a tiny quantity of additional elements including copper, zinc, and magnesium—is recognized for its lightweight, high strength, and superior corrosion resistance.

Strength and Durability

Solid and durable are zinc alloy chandelier accessories. Whether in long-term use in a house environment or frequent on-and-off operations in a business, this material can resist several pressures and wear during daily use. The great strength of zinc alloy chandelier accessories guarantees the stability and safety of the chandelier, therefore preventing deformation or fracture during operation. Aluminium alloy is somewhat less hard than zinc alloy, even if it has excellent strength. Thus, zinc alloy might perform better in uses requiring more stress and load.

Design Flexibility and Malleability

Additionally, differences in design flexibility and malleability are present in zinc and aluminium alloys. Using precision die-casting technology, zinc alloy may create a range of intricate forms for chandelier accessories thanks to its malleability. This function lets designers freely express their ideas, producing unique and beautiful chandelier accessories. Zinc alloy may satisfy several design objectives, whether in a classic opulent style or a simple modern one. Chandelier accessory design also incorporates aluminium alloy because of its outstanding machinability and ductility. Though aluminium alloy is malleable, it might not equal zinc alloy in precision moulding, so it has an advantage in various aspects, including detailed processing and intricate structural designs.

Regarding corrosion resistance, both aluminium and zinc alloys do rather well. Chandeliers are frequently employed in many settings, particularly in humid or chemically corrosive surroundings where common metal materials are prone to corrode, compromising their lifetime. The excellent corrosion resistance of zinc alloys helps prevent environmental metal erosion, thereby preserving superb chandelier accessories for an extended period. Particularly after anodizing treatment, which generates a dense oxide film on the aluminium alloy surface, improving its corrosion resistance, it is also well-known for its excellent resistance. Regarding corrosion resistance, zinc and aluminium alloys offer a dependable defence.

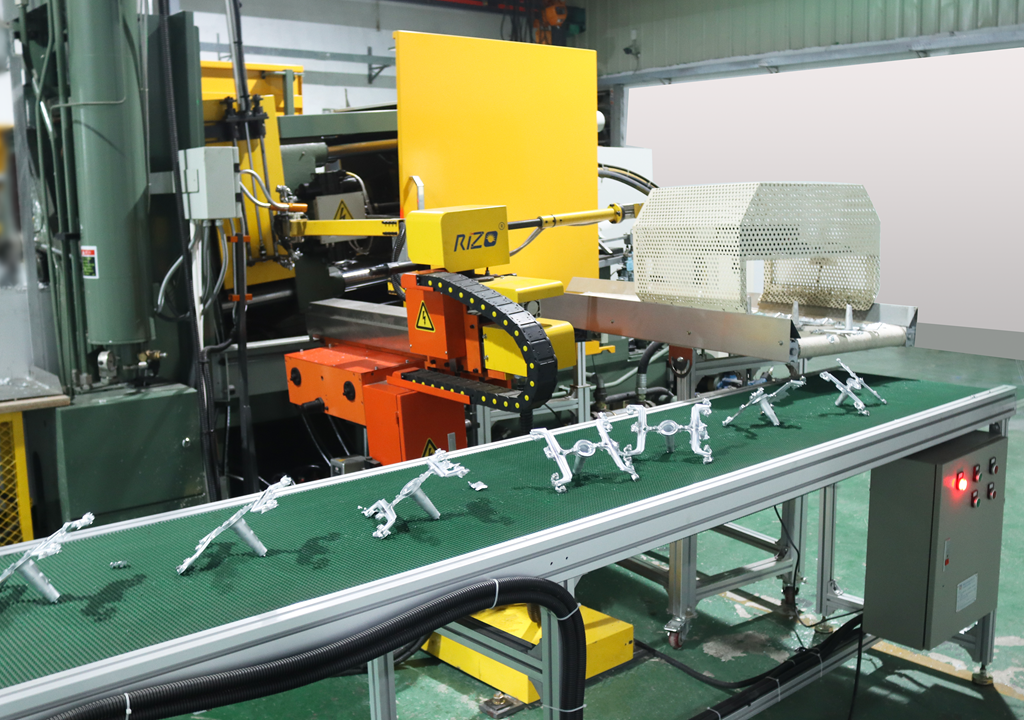

Manufacturing Techniques

Aluminium alloy and zinc alloy have different manufacturing techniques and traits. Usually made with precise die casting technology—where zinc alloy material is heated at high temperatures and then poured into moulds to cool and form—zinc alloy accessories. This procedure guarantees exact measurements and excellent uniformity of every chandelier item, ensuring reliable quality. The die-casting technique also makes creating accessories with complicated forms possible, satisfying designers’ demand for variation and elegance. Aluminium alloy accessories are produced by casting, extrusion, and forging, among other more varied methods. While casting is appropriate for making giant, complicated-shaped accessories, extrusion and forging techniques of the aluminium alloy may generate high-strength, exact accessories. Thus, the quality and performance of zinc and aluminium alloy chandelier accessories depend on the suitable manufacturing technique.

Another crucial comparative point for zinc and aluminium alloy chandelier accessories is the variation of surface treatment techniques. Offering numerous cosmetic effects and functional characteristics, zinc alloy can be electroplated, sprayed, oxidized, or otherwise surface treated. While increasing wear and corrosion resistance, electroplating can provide zinc alloy accessories with a smooth, brilliant metallic finish. Because spray paint offers a large spectrum of colours, accessories visually vary and fit many decorative designs. Apart from enhancing the corrosion resistance of the accessories, oxidation produces a distinctive surface texture, adding artistic value to the products. There are also several surface treatment techniques for aluminium alloy: powder spraying, electrophoretic painting, and anodic oxidation. Aluminium alloy accessories not only show a great range of colours and textures after anodic oxidation treatment, but they also have improved corrosion resistance, enhancing their attractiveness. Therefore, various surface treatment techniques for aluminium and zinc alloys offer more chances to design and use chandelier accessories.

Market Applications

Furthermore, zinc and aluminium alloys are different in their application market. Given their varied forms and robustness, the home décor market extensively uses zinc alloy chandelier accessories. Modern homes pay more and more attention to the appearance and personalizing power of decorations so that zinc alloy accessories can satisfy this need. Simple-style modern or classic chandeliers with a vintage look benefit from appropriate zinc alloy accessories. Their great strength and superior corrosion resistance guarantee that chandeliers can be kept in good condition for long-term use in a residential environment, not only prolonging the lifetime of the chandelier but also lowering maintenance expenses. Commercial and public settings, including hotel lobbies, restaurants, and conference rooms, increasingly feature aluminium alloy chandelier accessories. Aluminium alloy is lightweight and easy to work with; it may be used to construct primarily shaped, ornamental chandeliers that improve the general class and ambience of the surroundings. Furthermore, in the high-end and bespoke chandeliers market, aluminium alloy and zinc alloy accessories have benefited since they satisfy varied consumer needs for distinctive style and excellent quality.

Environmental Friendliness

For both zinc and aluminium alloys, environmental friendliness is a significant factor. Good recyclability characterizes zinc alloys; old zinc alloy accessories can be remelted into new goods. In line with ideas of sustainable development, this procedure saves resources and lowers waste creation. Zinc alloy materials need relatively little energy during manufacture, which increases their environmental friendliness even more. Zinc alloy requires less energy during melting and processing than other metal materials, lowering greenhouse gas emissions and energy consumption. The high recyclability of aluminium alloy also helps to significantly reduce its carbon footprint since recycling aluminium uses only 5% of the energy needed to create primary aluminium. Further lowering environmental impact are some environmentally friendly technologies applied in the manufacturing and processing of aluminium alloy. Thus, in line with contemporary green trends, aluminium and zinc alloys provide dependable environmental protection.

Chandelier accessories made of aluminium and zinc alloys have benefits and drawbacks that are appropriate for particular purposes and surroundings. Applications needing more stress and load benefit from zinc alloy’s exceptional strength, superb malleability, and outstanding corrosion resistance. Design and appearance benefit clearly from its precision die-casting technology and varied surface treatment techniques for zinc alloy accessories. Aluminium alloy is appropriate for locations needing a lightweight construction and great strength since it is lightweight, solid, and reasonably corrosion-resistant. Aluminium alloy accessories perform effectively in public and commercial uses because of their several manufacturing techniques and surface treatments. Regarding environmental friendliness, these materials satisfy contemporary green environmental criteria using low-energy production techniques and excellent recyclability.

When deciding between aluminum and zinc alloy chandelier accessories, the critical thing to consider is their relative benefits and drawbacks depending on particular requirements and application settings. Understanding the qualities and uses of these two materials will help you make a better-informed decision, therefore offering the best assurance for your chandelier’s quality, performance, and appearance. Whichever material you decide on, aluminum or zinc alloy, will provide outstanding quality and unique appeal to your chandelier.

Conclusion

Initially founded in 1996, Honjenny is a worldwide producer of precision metal components. Providing robust solutions for sectors including home hardware, perfume bottle caps, and consumer electronics, Honjenny specializes in zinc alloy and aluminum alloy die-casting technology. Consider contacting Honjenny if you are seeking a producer of aluminum or zinc alloy chandelier accessories.

Also, Read The Following: hot air balloon carriage.